Industrial Solutions Gyratory crushers - ThyssenKrupp

2022.11.21 thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e.

More

Unveiling the Advantages and Applications of

2023.2.28 Gyratory cone crushers are essential machines in the mining and construction industries, used to crush hard and abrasive materials into smaller pieces. In this article, we will provide a detailed

More

China Gyratory Crushers, Gyratory Crushers Manufacturers,

China Gyratory Crushers manufacturers - Select 2023 high quality Gyratory Crushers products in best price from certified Chinese Mining Machine, Crusher Machine

More

Gyratory Crusher Market Report Global Forecast From 2023

2019.11.11 Market Overview: The global gyratory crusher market is projected to grow from USD X.XX Billion in 2022 to USD X.XX Billion by 2030, at a CAGR of 5.1% from

More

New Used Primary Gyratory Crushers for Sale

1 天前 Savona Equipment is your source for New, Used, and Reconditioned Gyratory Crushing Equipment of many types and brand for large primary ore crushing, secondary, and tertiary fine material as well

More

Gyratory Crushers - FLSmidth Dorr-Oliver Eimco

Gyratory Crushers TC, NT and TS model crushers. Open the catalog to page 1. Our experience with Mining Industries (Minerals, Cement, and Aggregate) has resulted in a complete line of Gyratory Crushers to

More

Mining crushers SuperiorTM MKIII Primary Gyratory

2022.12.28 Superior™ MKIII primary gyratory range Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Metso Outotec’s

More

Top service gyratory crusher - FLSmidth Dorr-Oliver Eimco

Using today’s most modern analysis techniques, FLSmidth’s TS gyratory crushers are structurally sound from the inside out. With the Top Service design, FLSmidth not only

More

Selecting the Right Crushing Equipment Agg-Net

2015.10.28 Attrition crushers – which use both impact and grinding to shear the material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilize

More

THE EFFECT OF LINER WEAR ON GYRATORY

2011.6.21 Gyratory crushers are frequently used for first stage sizing in the minerals processing industry and are typically critical path fixed plant equipment. Hence any associated downtime or inefficient ...

More

Type of crushers and their difference - JXSC Mining

2019.12.10 There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher

More

Gyratory Crusher (Gyratory Crushers Explained)

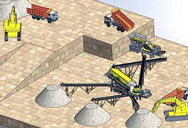

A primary crusher is designed to receive run-on-mine (ROM) rocks directly from the mines. Gyratory crushers typically crush to reduce the size of aggregate to a maximum of about one-tenth of its original size. Gyratory

More

Crushers - QueensMineDesignWiki

2023.11.13 The primary operating costs of a crusher are parts and labour for maintenance, which can vary approximately twice as much as the power for the motor. Gyratory crushers generally cost less than $1500 per hour to run, while Jaw crushers cost less than $200, including electricity (Infomine, 2008). Rules of Thumb

More

What are the functions of a gyratory crusher in mining?

2023.6.6 Gyratory crushers are designed for high capacity operations, and are often used in both open pit and underground mining operations. A gyratory crusher is a type of primary crushing equipment used ...

More

Superior™ MKIII Series primary gyratory crushers - Metso

Superior™ MKIII primary gyratory crushers all can include SmartStation, which combines innovative monitoring tools. Tools such as **VisioRock® and VisioTruck® along with expanded sensors on the equipment and bin/hopper, enabling intelligent measurement and automated-control of crushing operation for optimal ore processing and distribution.

More

Everything you need to know about Crushers in Cement

The largest gyratory crushers in current use attain throughputs of over 6000t/hour and have feed openings 1500mm x 4400mm in size (A x B), while the discharge graps range in width from 150 to 250mm. A jaw crusher designed for a certain throughput rate can accept larger pieces of rock than the normal gyratory crusher.

More

Mathematics Free Full-Text Mathematical Modeling and

2023.5.17 Such crushers are promising for use in mines to crush rocks laid in the developed space. Mathematical modeling and optimization of the design parameters of the working chamber and the executive body (roll) of a single-roll gyratory shaft crusher, designed for crushing strong rocks, was performed in this paper. A differential equation

More

Gyratory Crusher SpringerLink

2023.5.11 Gyratory crusher is a crushing equipment that uses the gyratory motion of the crushing cone in the conical cavity inside the shell to extrude, bend, and impact materials, for the purpose of coarse crushing of the materials of various hardness. It was invented in the USA in the 1870s. The equipment specification is usually represented by

More

(PDF) Torque Analysis of a Gyratory Crusher with the

2021.8.13 gyratory crushers, it is necessary to calculate their power and torque accurately. The discr ete element method (DEM) has been commonly used in several mining applications and is a powerful tool to

More

Gyratory crusher (adapted from ThyssenKrupp,

Pothina et al. (2007) developed an analytical model for energy consumption of gyratory crushers by using CSS and feed size variations. However, the feed fragmentation in this model is based on the ...

More

As a primary crusher, what are the advantages and

2021.3.25 In a large production line, the energy consumption is much lower than large and medium-sized jaw crushers. Maintenance period: Due to the simple structure of the machine, the maintenance period is short, and the daily operation is simple: The structure is complex and the equipment price is high. The maintenance period is long

More

thyssenkrupp extends gyratory crusher winning streak

2020.2.12 thyssenkrupp Industrial Solutions continues to strengthen its place as a leading manufacturer and supplier of gyratory crushers for the Australian mining market. The company finished off 2019 by ...

More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

1. Double-chamber gyratory crusher is a crusher machine that continues working with a double-chamber. The crusher equipment changes the discontinuous working mode of single chamber of jaw crusher. 2. The characterize is that producing more fine products under the condition of larger discharge port. Under the premise of ensuring fine products ...

More

Gyratory Crusher Market Report Global Forecast From 2023

The global gyratory crusher market is projected to grow from USD X.XX Billion in 2022 to USD X.XX Billion by 2030, at a CAGR of 5.1% from 2022 to 2030. The growth of the market can be attributed to the increasing demand for crushed stones for various applications such as construction, mining, and quarrying. Moreover, the growing infrastructure ...

More

Crushing and Screening Handbook - AusIMM

2021.6.24 TABLE OF CONTENTS Chapter Subject / section name Preface Table of Contents Metso’s Mining and Construction Technology 1 Quarry Process + Process Integration and Optimization (PIO) 2 Feeders 3 Crushing Equipment 3 C-Series Jaw Crushers 3 Superior MK-II Primary Gyratory Crushers 3 GP Series Cone Crushers 3 MP

More

Selecting the Right Crushing Equipment Agg-Net

2015.10.28 Cone and gyratory crushers Cone and gyratory crushers are both gyrating-shaft machines. They have a main shaft that gyrates and provides the crushing motion. Crushing takes place between a fixed outer crusher member (the concave ring) and a moving inner crushing member (the mantle) mounted on the gyrating shaft assembly.

More

Gyratory Crushers - FLSmidth Dorr-Oliver Eimco - PDF

FLSmidth’s solution to a unique crushing application in Canada was a custom designed 72”x 89” Gyratory Crusher. In addition to this crusher, multiple dual pinion drive crushers were designed and successfully installed for the Minnesota (USA) Iron Ore Range. Numerous Hard-Rock applications that required oversized motors prompted FLSmidth to...

More

Selecting the right type of crushing equipment - Quarry

2016.4.7 Compression crushers – which squeeze the material until it breaks. Impact crushers – which use the principle of rapid impact to shatter material. A ttrition crushers – which use both impact and grinding to shear material. Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle.

More

Buyer's Guide: Crushers - Equipment Contracting

Cone Crushers. A cone (or “conical”) crusher breaks down material with the use of an eccentric rotating head and a bowl. It is often used as a secondary or tertiary crusher. It is best for crushing material 200 mm and less. Advantages of a cone crusher include high productivity and low operating costs.

More