Sj Series Jaw Crushers for Primary or Secondary

2023.10.24 Sj Series Jaw Crushers for Primary or Secondary Crushing Contact Now Inquiry Basket Find Similar Items Similar Items

More

Jaw Crushers - Astec

2 天之前 Jaw Crushers Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing

More

Jaw Crusher - The widely used primary crusher for big size

2023.8.9 Jaw crushers are often used for primary crushing in mine material crushing. Jaw crusher is an equipment developed for aggregate crushing of highways, railways,

More

Crushing - Metso

From large primary jaws and gyratories to cone and impact crushers for tertiary and quaternary finishing, Metso equipment is manufactured to meet your material reduction

More

Hi-Pro Primary Jaw Crusher - CPC Crushing and

4432 Hi-Pro Primary Jaw Crusher mounted on civil foundations at a 200 TPH Crushing Plant. Hi-Pro Series Primary Jaw Crushers are among the

More

China Jaw Crusher Manufacturers, Suppliers, Factory - Good Price Jaw ...

HBM is one of the most professional jaw crusher manufacturers and suppliers in China since 1999, specialized in providing high quality machines and equipment with competitive

More

chinese jaw crusher function - LinkedIn

2023.6.19 Here are some key functions and features commonly found in Chinese jaw crushers: Primary Crushing: Chinese jaw crushers are primarily used for crushing large

More

Energy consumption of a laboratory jaw crusher during normal and high ...

An energy consumption measurement system was developed and a series of experiments were conducted to analyze the energy consumption and its dependance on the input

More

Jaw Crushers - AGGRETEK Jaw Crushers for

AGGRETEK highly versatile jaw crushers offer reliable operation and adaptability in mining, quarrying and recycling. Typical applications for jaw crushers are; Ore Mining. Rock Quarries. Sand and Gravel. Construction

More

Application of analytical hierarchy process to selection of primary crusher

2014.7.1 The crushing equipment standard to the mineral industries has been gyratory, double toggle jaw, single toggle jaw, high speed roll, low speed sizer, impactor,

More

Jaw Crusher – Conmix Crusher

Jaw Crusher is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models. Jaw Crusher is mainly used as the primary crusher. It can be

More

Mining Crusher - China Crusher, Jaw Crusher

FOB Price: US $1777 / piece. Min. Order: 1 piece. Product Description Product Description PE300x500 details Hengtong Model PE300x500 jaw crusher feeding size is 250 mm, output size is 25-85 mm, capacity is 25-85 t/h.

More

How to Choose Stone Crusher in Different Stages?

2023.1.18 The jaw crusher can handle ore with high moisture and high viscosity, and it is not easy to cause blockage. Generally, small quarries and mineral processing plants mostly use jaw crushers as

More

Stone Crusher In Ethiopia - LinkedIn

2022.8.5 Ethiopia stone jaw crusher has high reduction ratio and increased capacity with any feed materials. This is achieved through several unique features such as higher crushing speed, optimized ...

More

Material Selection for Crusher Jaw in a Jaw Crusher

2015.5.2 There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses ... reduced in the primary crushing stage; this can reduce the lump of 1.5m to 1020 cm using jaw crushers. - Primary ... Material Selection for Crusher Jaw in a Jaw Crusher Equipment . adopted for various designs (Chan and Zhou ...

More

Primary Jaw Crusher Stone Crusher FUREIN Machinery

2023.9.24 The primary jaw crusher is mainly used to crush all kinds of stones. As long as the compressive strength of the stone is not more than 320 mpa, it can be broken. Primary crusher is essential equipment in the stone crushing and processing production line of high and medium hardness stone.

More

The Complete Guide to Primary Crushing, Secondary Crushing

2023.2.28 Primary, secondary, and tertiary crushing are three stages in the comminution process that break down large rocks into smaller pieces of varying sizes. Each stage uses different types of crushers and has distinct advantages and disadvantages. This article provides a comprehensive guide to primary, secondary, and tertiary crushing.

More

What is a Primary Crusher? - machinerypartner

A primary crusher breaks up large pieces of rock or concrete from the blasting or excavation process and turns them into smaller, more manageable chunks. This is the first step in the crushing process. The smaller pieces can then either be pre-screened or fed directly into a secondary impact or cone crusher.

More

Crushers - All crusher types for your reduction needs - Metso

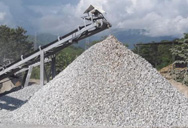

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.

More

What Is Primary, Secondary, and Tertiary

2021.1.10 The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on

More

Coarse Crushing Cone Crusher Or Jaw Crusher Is

2022.12.9 The cone crusher is suitable for coarse crushing of various hard and brittle materials with large output. The design of the deep V crushing cavity of the jaw crusher prevents the material from being

More

What Is an Impact Crusher and What Can It Do for You?

2021.1.10 An impact crusher, or impactor, is one of several types of crushing machines, including jaw crushers, hammermills, and cone crushers, that is manufactured for the purpose of processing raw materials, like concrete or asphalt, among many others, to reduce them in size. Used in a wide variety of applications, including aggregate crushing,

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023.2.28 The primary crusher’s function is to reduce the size of the rock or stone for easier handling and transportation. The primary crusher is usually a jaw crusher or a gyratory crusher, which operates by compressing the material between two surfaces. The jaw crusher works by moving the material between a fixed and a moving plate.

More

Advantages of Primary Jaw Crusher - LinkedIn

2023.3.8 Some of the main advantages of primary jaw crushers include: High capacity: Jaw crushers are designed to handle large volumes of material, making them ideal for high-capacity crushing applications ...

More

Trio® Crushing Equipment Weir

These crushers produce high-quality aggregates at a high production rate. The reduction ratio of a horizontal impact crusher is much higher than that of a jaw or cone crusher. The Trio® APP series is the larger of the two crushers and is used for primary stage crushing of larger feed sizes.

More

Jaw Crushers Price, 2023 Jaw Crushers Price ... - Made-in

Jaw Crushers Price - Select 2023 high quality Jaw Crushers Price products in best price from certified Chinese Jaw Crusher Machinery manufacturers, Mining Jaw Crusher suppliers, wholesalers and factory on Made-in-China ... High Quality Crushing Machine Supplier PE Series Jaw Crushermining Stone Aggregate Crushing Plant Equipment,

More

Jaw Crushing Price, 2023 Jaw Crushing Price Manufacturers

Jaw Crushing Price - Select 2023 high quality Jaw Crushing Price products in best price from certified Chinese Jaw Crusher/crushing Machine manufacturers, Jaw Crushing Equipment suppliers, wholesalers and factory on Made-in-China. ... Stone Crushing Jaw Crusher for Primary Granite Crusher Machine Price. US$ 3850-4650 / Piece. 1 Piece ...

More

As a primary crusher, what are the advantages and

2021.3.25 The structure of the jaw crusher mainly includes the frame, the eccentric shaft, the large pulley, the flywheel, the side guard plate, the toggle plate, the toggle plate rear seat, the clearance screw, the return spring, the fixed jaw plate and the movable jaw plate and other components. The crushing method of jaw crusher is curved extrusion type.

More

What Is The Difference Between PE Jaw Crusher And PEX Jaw Crusher ...

2023.3.30 The working part of a jaw crusher consists of two jaw plates, one is a fixed jaw plate (fixed jaw), which is vertically (or slightly outwardly inclined at the upper end) fixed to the front wall of the machine body, and the other is a movable jaw plate (movable jaw), which is tilted in position and forms a crushing cavity (working cavity).

More