Cement Production in Nigeria Encyclopedia MDPI

2021.9.16 Nigeria possesses the largest cement industry within West Africa, with at least 12 registered companies amounting to a merged cement capacity of 58.9 Mt/yr. Dangote Cement is the largest cement producer in Nigeria and West Africa,

More

Thermoeconomic and environmental analyses of a dry process cement ...

2017.9.15 The increase in the production of cement witnessed in Nigeria was majorly attributed to the abundant availability of raw materials and the installation of new and

More

Health Risk and Environmental Assessment of Cement Production in Nigeria

2021.8.30 Nigeria possesses the largest cement industry within West Africa, with at least 12 registered companies amounting to a merged cement capacity of 58.9 Mt/yr.

More

Thermoeconomic and environmental analyses of a dry process cement ...

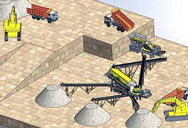

2017.9.15 The process was divided into ten basic unit operations, which are: drilling, explosive charging, mucking and hauling, crushing, raw material preparation, pre

More

(PDF) Cement Industry and Climate Change in

2022.8.1 Nigeria has the largest cement industry in West Africa, with an aggregate capacity of 58.9 million metric tonnes (MMT) per year. ... 40% more cost intensive in cement production than the dry ...

More

(PDF) Energy and Cost Analysis of Cement

2013.1.1 PDF The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. Energy consumption data collected... Find, read and cite all the research ...

More

Performance Indicators for Sustainable Cement

2018.12.1 Using the Analytic Hierarchy Process (AHP), three cement manufacturing companies in Ogun State, SouthWest , Nigeria were investigated to determine how best they conform to industry best...

More

(PDF) Health Risk and Environmental Assessment of Cement Production

2021.8.30 In Nigeria, limestone and marble are the main minerals of cement production. The conversion of this limestone into cement by heat releases carbon dioxide

More

Analysis of the contribution of imported and locally

This study attempted to examine the trends of supply and consumption of cement in Nigeria with a view to assessing the prospects of the shift of emphasis from cement import to

More

Profile on Nigerian Cement Industry - D-8 Organization

ORDINARY PORTLAND CEMENT 42.5 M MTP o _90 43.3MMTPA SAGAMU MFAMOSI BENUE 0B ggUA) CCNN sox0T0 puRECHEM STATE OGUN CROSS RIVERS BENUE

More

(PDF) Health Risk and Environmental Assessment of Cement Production

2021.8.30 Dangote Cement Plc, the indisputable biggest producer in Sub-Sahara and Nigeria with an installed capacity of. 48.6 Mta and 32.3 Mta respectively, just recently added 3 million tonnes to its ...

More

Energy and Cost Analysis of Cement Production Using the

This paper presents the thermodynamic analysis of a cement production process in Nigeria. The process was simulated in HYSYS. Exergy analysis is an analytical tool that evaluates the irreversibility and the exergertic performance of a process as well as provides identification of possible improvements in the process. The study indicates the ...

More

Thermoeconomic and environmental analyses of a dry process cement ...

2017.9.15 In this study, the thermoeconomic and environmental assessment was performed to identify key energy efficient opportunities and technical improvement potentials of the production of dry cement in Nigeria. The process was divided into ten basic unit operations, which are: drilling, explosive charging, mucking and hauling, crushing, raw

More

Assessment of Capacity Utilization in the Nigerian

2023.7.27 demand for cement in Nigeria and the need 10 satisfy it has pushed forward the cement production to do something in the capacitv Of the production process. In this study some tools are

More

Deep Decarbonization of the Cement Sector: A Prospective Environmental ...

2021.12.11 One of the top carbon dioxide (CO 2) sources is the production of cement, an important binding material around the world.Within this hard-to-abate sector, CO 2 is mainly released by the reactions involved in clinker production, whereas fuel combustion, generally coal, petcoke, and natural gas, entails the remnant CO 2 direct

More

1,2,* , Oludolapo A. Olanrewaju , Kevin J. Duffy

2022.4.6 operate mainly in cement finishing mills, while others perform the whole process, from raw materials to cement production. Cement plants in South Africa use several megawatt-hours per year, with annual limits ranging from 55 to 194 megawatt hours (MWh) [21]. The greenhouse gas (GHG) emissions from energy consumption are the

More

Energy and Cost Analysis of Cement Production Using

2021.8.24 Keywords: Wet Process; Dry Process; Cement; Crushing; Milling; Nigeria . 1. Introduction . Cement and/or clinker (cement primary input) is a com- modity being produced in over 150 countries of the world [1]. It is an essential input into the production of concrete needed for building purposes and other con- struction related activities.

More

Benchmarking energy utilization in cement manufacturing

2017.4.9 Description of the cement production process. Portland cement is the most common type of cement used in the world and is composed primarily of calcium silicate minerals in the representative proportions shown in Table 1 (Huntzinger and Eatmon 2009; Tennis et al. 2011).The raw materials are quarried or mined and transferred to the

More

Evaluation of optimization techniques for predicting

2023.3.20 University in Ota, Ogun State, Nigeria. In 2004, he earned his MSc in Industrial and Production Engineering from the University of Ibadan in Nigeria. He has worked in the cement industry, specifically with the French conglomerate Lafarge cement. Between 2005 and 2015, he worked as a Process Engineer and as a Process Manager

More

Thermoeconomic and environmental analyses of a dry process cement ...

2017.9.15 The production of cement in Nigeria cement plants is majorly based on dry kiln process. The process is carried out by combining a mixture of calcium carbonate in limestone and other raw materials such as silica in shale, alumina and iron oxide in red alluvium and small quantities of other minor minerals, chemically combined through

More

Update on Nigeria, September 2023 - Cement industry news from Global Cement

2023.9.6 Update on Nigeria, September 2023. Dangote Cement felt compelled to issue a statement clarifying its prices at the end of August 2023. In the release it stated what its ex-factory price was in Nigeria and added that transport costs and the location of a delivery could add additional expense. It made the declaration in response to alleged ...

More

(PDF) Environmental and Health Implications of

2021.1.1 These industrial plants for cement production involves a high energy intensity process marked with high-level consumption of fuel for clinker making which in turn results in releasing emissions ...

More

Environmental and Health Implications of Cement

2023.8.13 Cement Production, Emission Generation, Health and Environmental Impact, Sustainability Received: May 5, 2021 / Accepted: May 31, 2021 / Published online: July 26, 2021 @ 2021 The Authors.

More

Energy and Cost Analysis of Cement Production Using

2017.12.5 Keywords: Wet Process; Dry Process; Cement; Crushing; Milling; Nigeria . 1. Introduction . Cement and/or clinker (cement primary input) is a com- modity being produced in over 150 countries of the world [1]. It is an essential input into the production of concrete needed for building purposes and other con- struction related activities.

More

Cement kiln dust - ScienceDirect

2022.1.1 The cement production process is one of the most energy-consuming processes and has a strong environmental impact. The main impact on the energy consumption of cement production is the burning process of cement clinker in a rotary kiln, and the energy costs associated with burning cement clinker constitute 50-75% of

More

Energy and Cost Analysis of Cement Production Using the Wet

2014.6.19 In Nigeria, cement production grew rapidly from 2 million tonnes in 2002 to 17 million in 2011 [4]. This has led to the Nigeria cement industry accounting for 63.6% of the West African region’s cement output in 2011. ... (Table 1 4) that the average total energy cost of cement production by the wet process using power from national grid and ...

More

Thermodynamic Analysis of Cement Production Process Plant in Nigeria

Cement production industry being highly energy intensive requires a major goal of minimizing energy cost and environmental effects. This paper presents the thermodynamic analysis of a cement production process in Nigeria. The process was simulated in HYSYS. Exergy analysis is an analytical tool that evaluates the irreversibility and the exergertic

More

Sustainable Ready-Mixed Concrete (RMC) Production: A

2023.5.17 This study aims to examine whether ready-mixed concrete (RMC) production in Nigeria is sustainable. This study proposes that RMC production will be sustainable, assuming the RMC plant, RMC products, plant management, RMC supply, RMC quality, and demand for RMC are sustainable. Based on a constructivist worldview,

More

Nigeria: challenges abound - International Cement Review

2022.12.23 According to Nigeria’s National Bureau of Statistics (NBS), the country’s GDP growth rate in 2021 was 3.4 per cent, a recovery from the 1.9 per cent contraction in 2020. One cannot discount the base effect as the 2021 recovery was supported by the re-opening of economic sectors and increased vaccination rates.

More

Decarbonization options for cement production process: A

2022.7.15 The long-term environmental targets require significant cuts of CO 2 emissions in fossil fuel-intensive industrial processes. Currently, the cement production sector is responsible for approximate 8% of world anthropogenic CO 2 emissions. The present paper assesses from the technical, environmental and economic point of view

More