Synthesis, characterization and properties of organically

2020.4.14 A new process for manufacturing organically compounded bentonite was developed successfully based on the organic intercalation and layered structure of bentonite. The main steps in the proposed process included wet sodium activation of bentonite ore,

More

(PDF) Bentonite processing - ResearchGate

2013.1.1 The bentonite beneficiation were carried out in two stages [9]; samples were milled, screened, washed with distilled water and dried

More

How to process bentonite and what is it used for?-SBM

2022.9.29 The process of organic bentonite processing: Raw ore → crushing → dispersion → modification (sodiumization) → purification → ammonium salt covering →

More

Granular Bentonite Preparation and Effect of Granulation

2020.3.6 To obtain bentonite granules with different sizes, a granulation method is proposed in this paper, in which bentonite powders experience the processes of wetting

More

Process Development Essential to Bentonite

2022.6.3 Bentonite Process Development Testing. The diverse nature of bentonite, paired with its potential for variation make a thorough

More

Bentonite production - Clariant Ltd.

Adsorbents 1,000+ needs, shaped up into a single solution: Bentonite. Clariant’s Adsorbents business is a world- leading provider of bentonite and synthetic material-based specialty products and solutions. The tailored

More

MANU – Handling of Bentonite Prior Buffer Block

2012.3.29 The aim of this study is to describe the entire bentonite handling process starting from freight from harbour to storage facility and ending up to the manufacturing

More

Preparation and characterization of nano porous bentonite

2015.1.15 The acid type and concentration are two important factors that influence the oil regeneration process [23]. The type of recovery process in treatment of waste

More

(PDF) Granular Bentonite Preparation and Effect of

2020.9.10 Hoffmann et al. [24] prepared bentonite pellets by using powder FEBEX calcium bentonite; the maximum size of the pellet is required to be 1/5 of the smallest size of the compacted specimen powder ...

More

Influence of binder concentration in zeolitic ZSM

2023.2.24 4 Conclusions. In this work, ZSM-5-based zeolite monoliths of woodpile configuration were produced through robocasting. The effect of bentonite clay binder concentration in the range of 40–60 wt.%

More

Polyethylene Wax Modified by Organoclay Bentonite Used in

2020.5.14 The process of dispersing bentonite in the polymer matrix is strongly dependent on the polymer clay compatibility because the processing of polymer blends necessitates knowledge of their rheological properties (viscosity). ... Wax usually used as a matrix for manufacturing models in the lost-wax casting method is characterized by long

More

Preparation and characterization of nano porous bentonite

2015.1.15 Bentonite powder plays an important role in the regeneration and clarifying of wastes [5]. The edges and faces of bentonite particles can adsorb cations, non-ionic and polar contaminants from environment [6]. The treatment of bentonite powder with inorganic acids is known as activation [7]. The exchangeable cations can be replaced by H + ions.

More

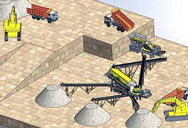

en/cost of bentonite manufacturing processing plant.md at

cost of bentonite manufacturing plant astroconsultants. bentonite processing plant cost bedfactory.co.Cost of bentonite manufacturing processing plant andntonite processing plant.The bentonite is processed into either a fine powder or granulated into a small particle or flake.Dry compaction method for the creation of bentoniteCost reduction: The new

More

Process Development Essential to Bentonite Processing Operations

2022.6.3 Bentonite is a member of the smectite group of minerals and is primarily made up of montmorillonite. As a smectite, bentonite exhibits a combination of several important characteristics that have lent it to such widespread use. Key properties of the smectite group include: ¹. 2:1 Expandable layers. High layer exchange. High base

More

ORGANIC INDUSTRIES PVT LTD.

2020.7.25 Bentonite. Organic has set up its bentonite processing facility in the year 2015 having one of the largest manufacturing facility of bentonite powder and lumps in India located in Bhuj the state of Gujarat equipped with state of the art manufacturing facility with a capacity of 4000Mts per month. An introduction to Bentonite which is a ...

More

How to process bentonite and what is it used for?-SBM

2022.9.29 1. The process of artificial sodiumization of calcium bentonite: Calcium-based soil raw ore → crushing → adding sodium carbonate (wet method also needs to add water) → mixing extrusion → rotary kiln drying → grinding → air classification → sodium-based soil products. 2. The processing flow of active (acidic) clay:

More

The Bentonite Construction Waterproofing Manual

2019.3.27 The result of this manufacturing process is a product that is able to contain the hydrated natural sodium bentonite, even when installed in a vertical position. Where flowing water is encountered, the bentonite is contained without being washed out. Graphical scheme of the overlap of BENTOFIX® BFG 5000. Manufacturing process of BENTOFIX®.

More

Physical Properties of Bentonite Download Scientific Diagram

Bentonite is one such pozzolanic clay material that is rich in SiO2 content. A little research was made to assess the performance of bentonite modified concrete. Based on those, an improvement in ...

More

Bentonite Powder Api 13 Sec 9 at Rs 3000/metric ton

Bentonite Powder Api 13 Sec 9 - Buy Bentonite Powder at best price of Rs 3000/metric ton by Neelkanth Fitraids And Mineral Products. Also find product list from verified suppliers with contact number ID: 21408311212 ... Moreover we have a testing team that inspects the manufacturing process of these products at various stages to make the best ...

More

Homogenization of bentonite upon saturation: Density and

2021.8.1 Bentonite structures are a core element of engineered barriers for geological repositories, preventing radionuclide release into the biosphere. These are often assemblies of elements with different densities (bricks, pellets, powder), or may contain regions of different density due to the building process (technological voids, powder segregation).

More

How to Dry, Grind and Granulate Your Bentonite

2023.5.27 Step 4: Grind the sodium bentonite to 200 mesh with a Raymond mill. Step 5: Mix 200-mesh bentonite powder, corn starch, zeolite and other main raw materials in a certain proportion and pour the mixture

More

11 benefits of bentonite clay: How to use it and

2023.10.24 2. Treating oily skin and acne. Bentonite clay’s adsorbent power may help treat acne breakouts and oily skin. The clay may help remove sebum, or oil, from the skin’s surface, and it may have a ...

More

IOP Conference Series: Earth and Environmental Science

he process of precipitation was immediately studied by adding bentonite suspension to the extracted stem juice. Method of preparation of suspension from bentonite powder: 200. g of bentonite powder is poured hot water (at a temperature of 80-85 0C, distilled water) in a ratio of 1:2 and left for a day until the suspension is ready.

More

Ferrochrome Slag as an Alternative Mould Material for Green

2022.1.18 The bentonite clay creates a bond with mould ingredients in the presence of moisture or water . Therefore, as moisture and bentonite clay concentration increases, the shear strength of slag mould increases. The moulding mixture contains 7% moisture, and 14% bentonite clay has 0.47 kg/cm 2 shear strength.

More

Minerals Free Full-Text Bentonite Powder XRD

2022.6.17 Bentonite is a claystone formed by a complex mineralogical mixture, composed of montmorillonite, illite, and accessory minerals like quartz, cristobalite, feldspars, carbonates, and minor amounts of iron oxy-hydroxides. Bentonite presents complexity at various scales: (1): a single mineral may present different chemical

More

(PDF) Granular Bentonite Preparation and Effect of

2020.9.10 Hoffmann et al. [24] prepared bentonite pellets by using powder FEBEX calcium bentonite; the maximum size of the pellet is required to be 1/5 of the smallest size of the compacted specimen powder ...

More

Bentonite Powder Trade Suppliers and Products - Arad

Bentonite powder had a total trade value of $852 million in the year 2020, placing it as the 2085th most traded product in the world. From 2019 to 2020, the total value of bentonite exported, suppliers, and products increased by 1.17 percent, going from $842 million to $852 million. ... Throughout the manufacturing process, they never use ...

More

Characterization of South African Bentonite and Kaolin Clays

2023.6.20 The present study aimed to investigate the mineralogical and morphological properties of two South African clays, namely bentonite and kaolin. These clays are mined in specific regions of the country but have not been fully characterized in terms of their properties for potential application in a number of industries. Bentonite was

More

Minerals Free Full-Text Geochemical, Geotechnical, and

Bentonite buffers at temperatures beyond 100 °C could reduce the amount of high-level radioactive waste in a deep geological repository. However, it is necessary to demonstrate that the buffer surrounding the canisters withstands such elevated temperatures, while maintaining its safety functions (regarding long-term performance). For this reason, an

More

Pellets/block bentonite barriers: Laboratory study of their

2021.10.1 The pellets were prepared for the EB project ( ENRESA, 2005) using a 100-t batch of bentonite extracted in 2001 also from the Cortijo de Archidona deposit. To manufacture the pellets the bentonite was dried and milled in a multi-step process to produce a fine grade powder with a water content of between 3.0 and 4.5%.

More